Enjoy Greater Material Strength With Ultrawear in Flint, MI

When strength and longevity matter, Ultrawear delivers. This proprietary thermal-chemical diffusion process from Woodworth Heat Treating is engineered to strengthen ferrous metals from the inside out. By introducing nitrogen and carbon into the base material, Ultrawear forms a durable ε (epsilon) carbonitride layer—commonly referred to as the compound or white layer—while enriching the material’s subsurface with a diffusion zone.

Unlike traditional coatings that sit on top of your part, Ultrawear transforms the steel at the molecular level. This nanotechnology enhances corrosion resistance, wear resistance, thermal fatigue strength, and overall serviceability without compromising dimensional accuracy or ductility.

Why Choose Ultrawear?

Ultrawear improves the physical properties of your components and extends their lifespan—especially in heavy-duty, high-stress environments. Here’s how:

Boost Strength & Hardness

Ultrawear creates a hardened outer layer that can reach up to 1200 Vickers or exceed Rockwell C 70, while the core material remains ductile. This dramatically improves resistance to impact, abrasion, and surface fatigue.

Better Performance Under Heat & Load

Designed for high-temperature environments, Ultrawear increases thermal fatigue resistance & retains material strength under repeated stress, making it ideal for rotors, drums, & other heat-cycled parts.

Customizable Diffusion Depth

The Ultrawear layer can be tailored from 10 to 100 microns, depending on your application & base material. This allows for precise treatment without affecting part tolerances or dimensional stability.

Flint’s FAQs About Ultrawear

You know steel—its properties, its potential, and its limitations. But when you’re looking to take durability to the next level, questions naturally come up. Whether you’re curious about how Ultrawear compares to coatings or wondering if it’s right for your application, we’re here with the answers.

Ultrawear is suitable for a wide range of ferrous metals, including:

- Low, medium, and high-carbon steels

- High-strength low-alloy (HSLA) steels

- Cast iron (gray, ductile, pearlitic-malleable)

- Tool steels and alloy steels

Common applications include:

- Rotors, drums, and hubs

- Forgings and stampings

- Die casting and injection molding dies

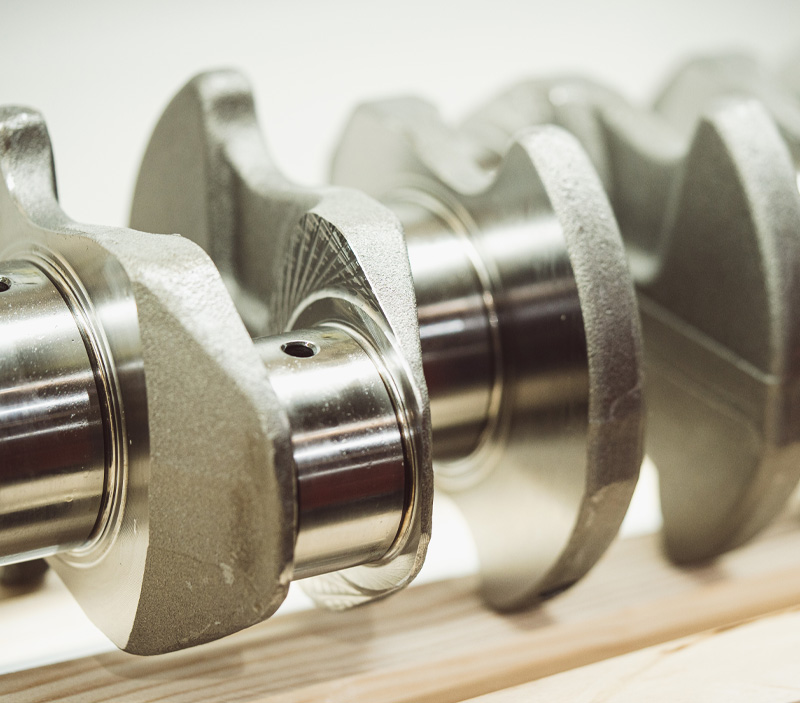

- Gears, shafts, and valves

- Mining, agricultural, and off-highway components

Ultrawear is not a coating—it’s a green nanotechnology diffusion process. It changes the material’s structure, not just the surface, which means no flaking, peeling, or post-machining issues. It preserves dimensional accuracy while significantly enhancing strength, wear life, and corrosion resistance.

The process is carefully controlled and suitable for parts of various shapes and sizes. Since it’s a diffusion treatment rather than a coating, Ultrawear maintains the original dimensions and tolerances, making it ideal for precision components with complex geometries.

Ultrawear has been shown to increase tensile strength by up to 40% and surface hardness by 10 Rockwell points over the core. It improves fatigue resistance and allows for potential cross-section reduction, helping OEMs reduce weight and material costs.

Yes. Ultrawear is considered a “green” technology. Because it is a diffusion-based surface treatment and not a coating, it avoids hazardous chemicals and eliminates the need for post-processing like stripping or recoating. It also helps extend the life of components, reducing scrap and material waste over time.

Ultrawear delivers performance that rivals or exceeds conventional ferritic nitrocarburizing (FNC) processes—but with greater control over diffusion depth, better material compatibility, and improved base metal properties. This makes it a cost-effective solution, especially when longer part life or reduced cross-section thickness can offset material or manufacturing costs.